Service Hotline

In the fast-paced world of consumer electronics, reliable electrical connections are the backbone of efficient product design. Among these, the Wire-to-Board Connector stands as a vital interface linking cable assemblies to printed circuit boards (PCBs). For procurement and engineering teams, understanding the diverse structures, types, and applications of these connectors is essential for optimizing performance, cost, and assembly efficiency.

Understanding the Structure of a Wire-to-Board Connector

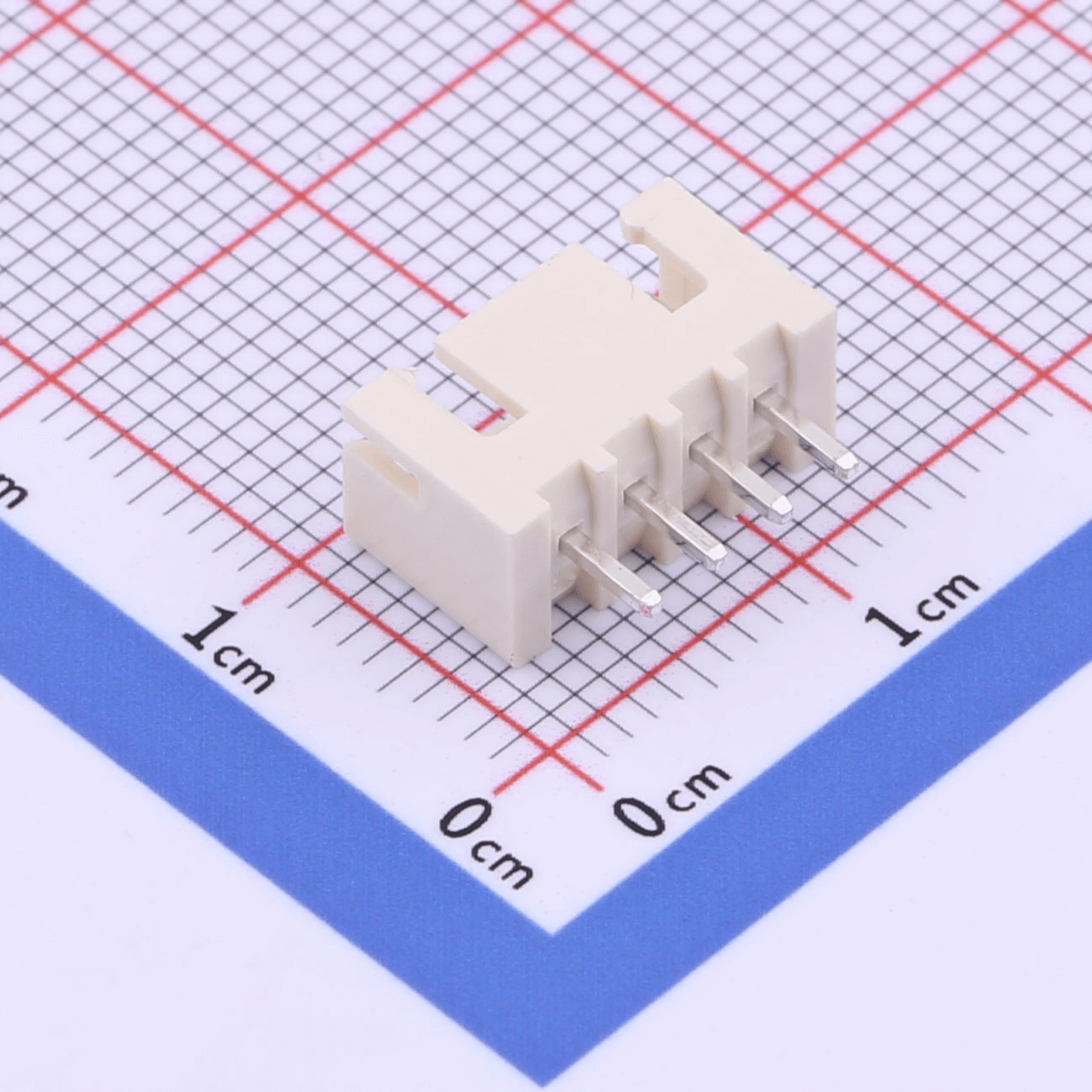

The Wire-to-Board Connector serves as a bridge between a conductive wire and the circuit board, enabling secure electrical transmission. Its structure generally includes three critical components: the housing, the terminal, and the contact interface. Each part contributes to the connector’s reliability, ensuring stable current flow and mechanical durability.

The housing, often made of thermoplastic materials, provides insulation and protection from environmental factors. The terminals, typically composed of copper alloys with gold or tin plating, ensure consistent conductivity. Finally, the contact interface defines the mechanical connection quality, influencing mating cycles and resistance performance. Understanding these details helps engineers select a Wire-to-Board Connector suited to specific operating conditions, from high-vibration automotive systems to compact mobile devices.

Main Types of Wire-to-Board Connector

The Wire-to-Board Connector family is diverse, with designs adapted to different assembly needs, space constraints, and current capacities. For consumer electronics, choosing the right type can significantly affect assembly speed, product durability, and maintenance simplicity.

1. Crimp Type Connectors

Crimp connectors are among the most widely used types. They employ crimped terminals attached to the wire using precise mechanical pressure, creating a strong and low-resistance joint. This design ensures long-term reliability and minimizes manual soldering. Such connectors are ideal for high-volume manufacturing environments where consistent quality is essential.

2. IDC (Insulation Displacement Contact) Connectors

IDC connectors enable rapid termination without stripping wire insulation. The terminal pierces the insulation layer to establish direct contact with the conductor. This approach reduces production time, making it valuable for consumer devices requiring fast and automated assembly. It also minimizes human error during cable preparation.

3. Solder Type Connectors

Solder connectors rely on molten solder to secure wires to contacts. While labor-intensive, this type offers high mechanical strength and excellent conductivity. It remains popular for prototypes or applications requiring tight electrical tolerances, such as power modules or precision instruments.

4. Screw Terminal Connectors

Screw terminal connectors provide a detachable connection using mechanical tightening. They offer flexibility for testing and maintenance, though they are less common in compact electronic assemblies due to their larger footprint. However, they are still relevant in industrial control panels or modular designs.

Key Parameters in Wire-to-Board Connector selection

selecting the right Wire-to-Board Connector involves evaluating electrical, mechanical, and environmental factors. Procurement and engineering teams should carefully consider:

Pitch size: Determines connector compactness and current rating.

Current capacity: Influences heat generation and conductor thickness.

Mating cycles: Reflects the connector’s expected lifespan.

Operating temperature range: Affects material choice and long-term reliability.

Locking mechanism: Ensures secure mating and prevents accidental disconnection.

Choosing the optimal configuration ensures not only stable performance but also reduces rework costs and field failures. Balancing miniaturization with reliability is especially critical in portable consumer devices.

Applications of Wire-to-Board Connectors in Consumer Electronics

The application scope of the Wire-to-Board Connector extends across nearly every segment of modern electronics. These connectors play a crucial role in ensuring robust communication between modules, sensors, and control units.

1. Smartphones and Wearables

In compact devices like smartphones, tablets, and wearable technology, Wire-to-Board Connectors enable internal module interconnections within tight spaces. The low-profile design supports compact PCB layouts and ensures stable signal integrity under vibration or movement.

2. Home Appliances

Consumer appliances depend on reliable Wire-to-Board Connectors to link control boards, power units, and display modules. Their ability to resist temperature variations and mechanical stress is essential for long product lifespans and safe operation.

3. Automotive and Smart Mobility

Vehicles integrate numerous electronic systems that rely on Wire-to-Board Connectors for communication between sensors, controllers, and infotainment devices. Connectors designed for automotive-grade vibration resistance and thermal endurance ensure dependable performance on the road.

4. IoT and Smart Home Systems

With the rapid expansion of the Internet of Things, Wire-to-Board Connectors enable efficient communication between edge devices and central hubs. Their versatility supports modular upgrades and scalability, reducing design complexity in connected ecosystems.

Manufacturing and Assembly Considerations

From an engineering standpoint, ease of assembly is as vital as electrical performance. A well-designed Wire-to-Board Connector must allow quick insertion, clear polarization, and repeatable mating. Automated assembly lines often rely on connectors with robust retention features to prevent misalignment. Procurement specialists should collaborate closely with design engineers to evaluate the total cost of ownership, including tooling, labor, and maintenance costs.

For high-volume electronics production, connector standardization simplifies inventory management and supports scalable sourcing. Working with reliable suppliers also ensures traceability and consistent product quality, which are crucial for international compliance and certification.

Future Trends in Wire-to-Board Connector Development

Technological innovation continues to refine Wire-to-Board Connector design. Future generations will likely feature enhanced current density, miniaturized housings, and higher mating reliability. The shift toward automated manufacturing will further emphasize precision alignment and zero-defect assembly. Moreover, as sustainability gains prominence, eco-friendly materials and recyclable components will play a greater role in connector design.

Conclusion

The Wire-to-Board Connector remains indispensable in modern electronics, offering the essential bridge between cabling and circuitry. For procurement and engineering professionals, mastering connector types, materials, and applications translates directly to improved product reliability and manufacturing efficiency. By understanding structural variations and selecting the appropriate specifications, teams can achieve optimal performance while maintaining cost control. As electronics continue to evolve, the role of the Wire-to-Board Connector will only grow more central in ensuring seamless connectivity and long-term dependability.