Service Hotline

Basic Concepts of FPC and PCB

Flexible Printed Circuits (FPCs) are circuit boards made from flexible substrate materials such as polyimide (PI) or polyester (PET), allowing them to bend, fold, and adapt to various shapes and confined spaces. In contrast, Rigid Printed Circuit Boards (PCBs) are manufactured from rigid materials such as FR-4 and are typically used to support heavier electronic components.

The integration of FPCs and PCBs enables modern electronic devices to achieve more complex functionalities within limited space, meeting the growing demands for compact and lightweight designs.

Importance of Electrical Connectivity Between FPC and PCB

Reliable electrical connectivity between FPCs and PCBs is critical to the proper operation of electronic devices. High-quality connections ensure stable and reliable signal transmission, thereby enhancing overall product performance. In addition, the chosen connection method directly affects the size, weight, and structural design of the device.

Methods for Achieving Electrical Connectivity Between FPC and PCB

3.1 Connection Methods

Common connection methods between FPCs and PCBs include:

Soldered Connections

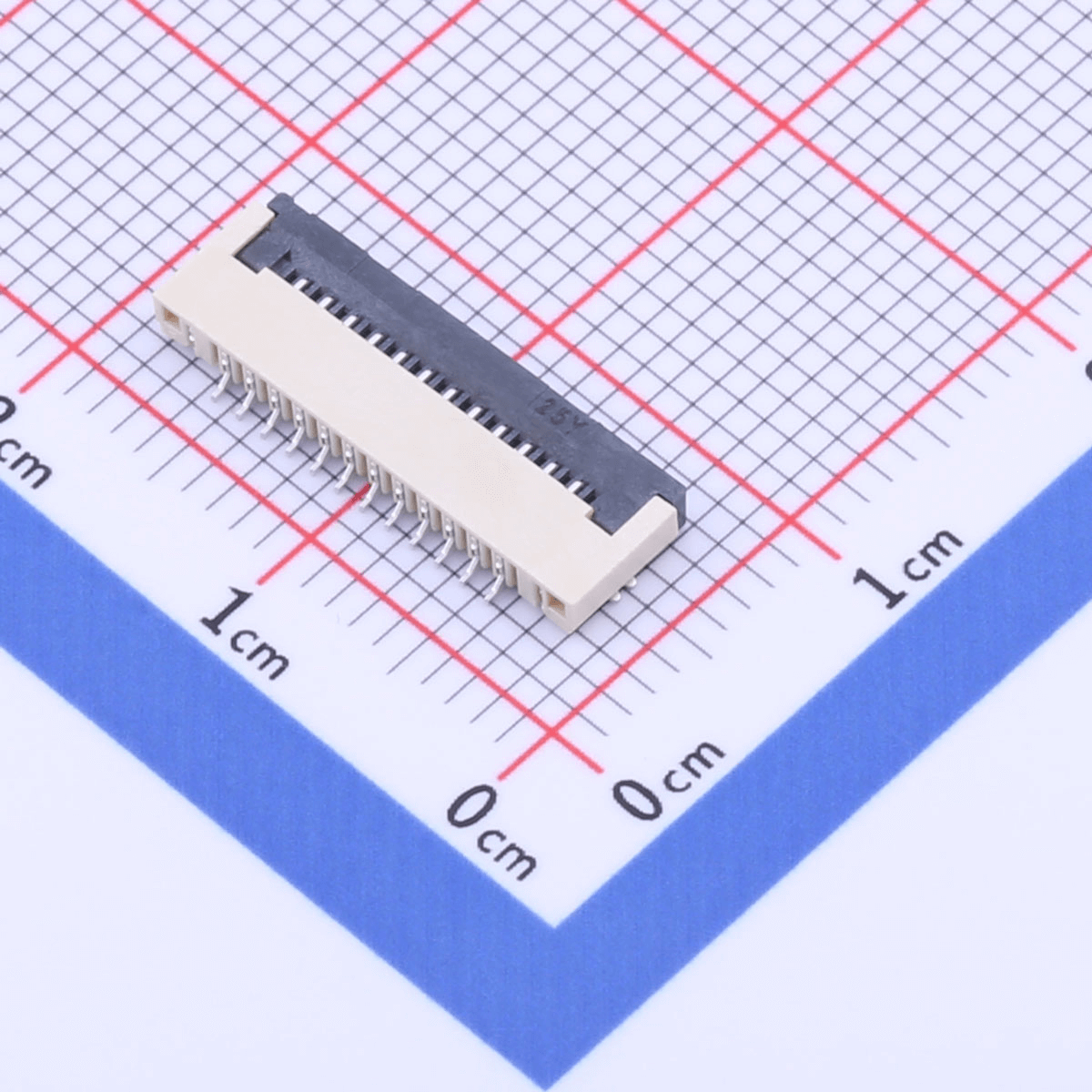

The metal pads of the FPC are soldered directly to the corresponding pads on the PCB. This is the most widely used method and is suitable for a broad range of applications.Connector-Based Connections

FPC connectors are used to link the FPC and PCB. This method allows easy assembly, disassembly, and maintenance, but may increase overall device size.Adhesive Bonding

In certain special applications, conductive adhesives can be used to bond FPCs to PCBs, ensuring electrical conductivity while reducing mechanical stress.

3.2 Material selection

The quality of electrical connectivity between FPCs and PCBs largely depends on material selection. Common FPC substrates include polyimide (PI) and polyester (PET), which offer excellent flexibility and thermal resistance. PCBs are typically made from FR-4 material, known for its good mechanical strength and electrical insulation properties.

When selecting materials, factors such as operating environment, temperature range, and electrical performance requirements must be carefully considered.

3.3 Soldering Processes

Soldering is one of the most critical steps in establishing reliable connections between FPCs and PCBs. Common soldering methods include:

Wave Soldering

Suitable for mass production, enabling fast and uniform soldering of FPCs to PCBs.Manual Soldering

Ideal for small-batch production and prototype development, offering flexibility and ease of adjustment.Reflow Soldering

Commonly used for surface-mount devices (SMDs), ensuring consistent solder joint quality.

During the soldering process, temperature and dwell time must be carefully controlled to prevent damage or deformation of the FPC materials.

Challenges in FPC-to-PCB Electrical Connectivity

Despite continuous advancements in FPC-to-PCB connection technology, several challenges remain in practical applications:

Thermal Management

FPC materials may deform under high temperatures, requiring strict temperature control during soldering.Mechanical Stress

Due to their flexibility, FPCs are more susceptible to mechanical stress, which may result in solder joint failure or damage.Signal Integrity

The interconnection between FPCs and PCBs may introduce additional resistance and inductance, potentially affecting signal transmission quality, especially in high-speed applications.

Future Development Trends

As electronic products continue to evolve toward miniaturization and higher performance, the requirements for FPC-to-PCB connectivity are becoming increasingly stringent. Future development trends may include:

Application of New Materials

The development of advanced flexible substrates and conductive materials will further improve connection reliability and performance.Automated Soldering Technologies

With the advancement of automation, automated soldering equipment will be more widely adopted to enhance production efficiency and soldering precision.Higher Integration Levels

Future electronic devices will feature higher levels of integration, requiring tighter and more efficient integration between FPCs and PCBs to meet market demands.

Conclusion

Electrical connectivity between FPCs and PCBs is an essential aspect of modern electronic device design. Through proper design practices, material selection, and optimized soldering processes, reliable and efficient connections can be achieved to ensure device performance and long-term reliability. As market demands and technological challenges continue to evolve, ongoing innovation in FPC-to-PCB connectivity technologies will play a crucial role in supporting the advancement of electronic products.